您好,歡迎訪問禹城泰瑞彩鋼復(fù)合板加工廠!

熱門關(guān)鍵詞:禹城彩鋼廠,禹城彩鋼復(fù)合板,禹城鋼結(jié)構(gòu)板房

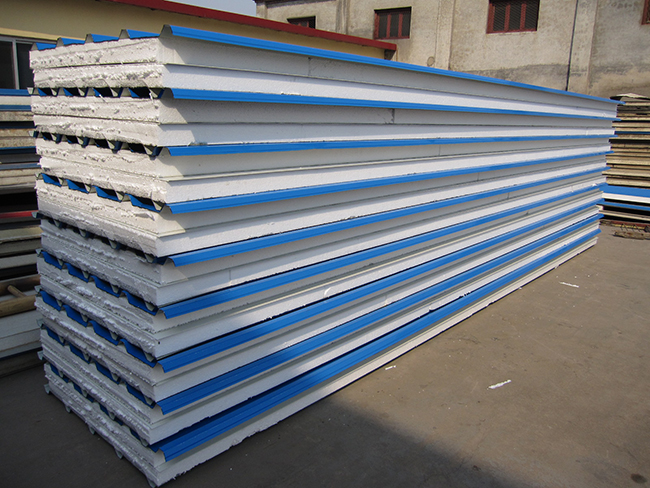

彩鋼板房

聯(lián)系電話:18765446878

咨詢熱線:18765446878(微信同號)

地址:禹城市十里望鎮(zhèn)山東國際商貿(mào)港往南660米

備案號:魯ICP備2023024436號 魯公網(wǎng)安備37010202001695號 網(wǎng)站地圖|XML|TXT

微信二維碼